Straightening Cut to Length Line

Product Details

| Model Number | HZP-1600*3-SS-009 |

| Cutting Width (mm) | 500 – 4000 mm |

| Cutting Speed(m/min) | 5 – 60 m/min |

| Leveling Precision(±mm/m) | 0.5 ±mm/m |

| Coil Width | 300-1500mm |

| Material Thickness(mm) | 0.3 – 3 mm |

| Coil Weight (T) | 15 |

| Sheet Length | 500-4000mm |

| Cutting Mode | hydraulic cut or pneumatic cut |

Product Description

cut to length line used for cutting coil to sheets by cross cut, then stacking the sheet to pallet, it is widely used in metal fabrication, punching, auto parts, coil processing, fittings, etc industries. it contains the mechnical parts, hydraulic part, electric part, pneumatic part and lubraicate part. Our advantage as below:

1, Technical team from Taiwan, designers have more than 20 years experience, It can help customers to find best quality solution

2, Quality Control team from Taiwan, They use Taiwan quality standard, that’s why we are No.1 in our industrial

3, Professional as we only produce cut to length line and slitting line. We pay all time for slitting line and cut to length line Research and Design, So we can get improve day by day

4, Skilled installation team to keep sure customer satisfy with their requirements.

cut to length line introduction

1, Raw material specification

| 1, Coil width: 500-1500mm | 2, raw material: SS, GAL, COPPER | 3, Coil weight: 5-25 T |

| 4, Coil ID: 508MM | 5, Line speed: 60m/min | 6, Control system: Siemens/ABB |

| 7, Drive: AC or DC | 8, Machine color: blue | 9, monthly production ability: 800-2000 T |

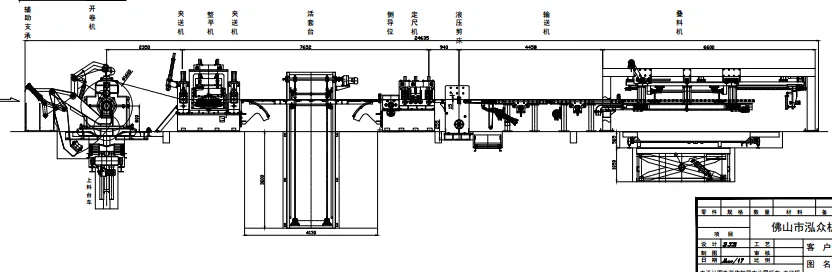

2, Machine composition

| 1, Coil loading car | 2, hydro decoiler | 3, Leveler (shear) | 4, loop bridge#1 |

| 5, Guider& NC length measure | 6, hydro shear | 7, belt conveyor | 8, stacker |

| 9, lift table | 10, move out roller table | 11, hydraulic system | 12, electric system |

3, Details description for cut to length line

(1) Coil loading car

Used to loading coil to decoiler mandrel, leveling working in rails, vertical lift power from cylinder, v type saddle

(2) hydraulic decoiler

Used to hold the coil, then open coil, feeding coil to next step, expansion and contractive by hydrualic power through wedge

(3) Pinch roller, leveler (crop shear)

Pinch roller used to pinch sheet to loop bridge, drive from motor power

Leveler used to leveling the uneven sheet to get best flatness, it consist of 19 rollers

(Crop shear used to cut the coil head and tail. or cut full coil to two half coils, power from hydaulic system)

(4) Loop bridge#1

Used to storage the enough coil to keep line working in best condition, also help to coodinate with each parts speed micro different, have sensor inside the pit to adjust each parts working speed in same

(5) NC length measure

Guider used to guiding sheet going with correct way to the slitter, manual adjust the width by hand-wheel

Slitter used to slitting big size coil to required multi-baby coils, the strips width depends on knife and spacer setting

(6) hydraulic shear

Used to shearing down the sheet which set in PLC as per production requirements, shear power from hydro cylinder or motor

(7) belt conveyor

used to conveying sheet to next, belt durable, seamless belt

(8) auto stacker, lift table, move out conveyor table

Auto stacking used to picking sheet from belt, then drop it down to lift table

Lift table under the stacker, it has sensor to detecting the sheet thickness then automatically drop as sensor signal coming.

Move out roller table used to move sheet out as this pallet is full, Roller moving power from motor.

Reviews

There are no reviews yet.